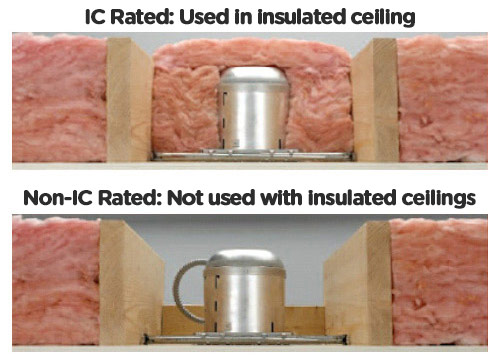

IC vs. Non-IC Rated LED Light

When to Use Fixtures Which Are Not IC Rated

Between the metal of the can and the ceiling insulation, non-IC rating fixtures need at least 3 inches of clearance. If you're feeling adventurous and want to tear down the roof, non-IC rated downlights are often found in remodels and ceilings without insulation, such as unfinished attics. The single can architecture of these units necessitates the use of an air pocket to dissipate heat.They're less costly than IC-rated fixtures, and they can handle higher-wattage bulbs.

You should use an airtight cover to prevent the insulation from touching the can when installing non-IC quality fixtures in an insulated ceiling. This allows you to insulate the area around the cover, which helps to avoid condensation, mold formation, and drafts. These covers are available premade or you can make your own out of rigid foam insulation and insulation foam.Only make sure there's at least 3 inches between the metal housing and all other components.

When to Use Fixtures Which Are IC Rated

IC-rated fixtures can be found in insulated or uninsulated ceilings, but they're almost always reserved for new construction rather than remodels. Just the outside can comes into contact with the insulation and stays cool enough to avoid combustion thanks to a double can or "can inside a can" configuration. As a result, the ceiling insulation will lie directly against the metal without posing a fire hazard.

You should upgrade your recessed lighting to LED without removing the whole fixture if you want to conserve electricity without the hassle of a home renovation project. Retrofitting LED downlights is as easy as screwing in a light. LED downlights, and most LED lights, help to minimize heat and energy consumption while still having a longer lifetime than incandescent and halogen alternatives.